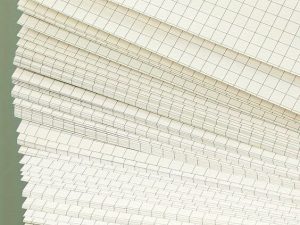

Lipase is produced from Aspergillus niger strain through fermentation, extraction and purification. The product is widely used in leather processing, animal feed, paper making, laundry and bioenergy industries.

Catalytic mechanism

Lipase is a serine hydrolase that can catalyze the hydrolysis of fatty acid glycerides to produce glycerol and fatty acids. The important feature of the hydrolysis reaction is that it occurs at the oil-water interface. This enzyme can also catalyze ester synthesis and transesterification reactions.

Operating conditions

| Temperature (ºC) | pH | Influenced by metal ions | |

| Operating range | 30 – 70 | 4.0 – 10.0 | Ca2+ and Mg2+ can promote enzyme activity, Mn2+, Fe2+ and Zn2+ can inhibit enzyme, and Cu2+ and EDTA have no obvious effect on enzyme activity. |

| Optimize | 55 -65 | 7.5 |

Specifications

| Specifications | Liquid | Powder form |

| Active | 100000u/mL | 100000u/g |

| pH (25ºC) | 6.0-7.5 | – |

| Specific gravity | ≤ 1.25g/mL | – |

| Fineness (Sieve ratio – 0.4mm) | ≥ 80% | ≥ 80% |

Determination of enzyme activity: 1g of concentrated enzyme powder (or 1mL of liquid enzyme), under certain temperature and pH conditions, hydrolyzes the substrate in 1 minute to produce 1µmol of fatty acid, which is 1 unit of enzyme activity, calculated in U/g (U/mL).

Dosage

In the paper industry: 0.04-0.10L/ton of pulp (activity is 100,000 units).

In bread production: 0.01-0.05kg/ton of wheat flour (enzyme activity is calculated as 100,000 units). The combination of this enzyme with xylanase, fungal α-amylase and glucose oxidase can improve the quality of noodle products.

In the leather industry: Use 0.02-0.06% (based on raw material mass, enzyme activity is 100,000 units), and operate at 30-40°C for 30-120 minutes. This enzyme is often used in combination with alkaline protease to optimize its efficiency.

In animal feed: is 0.01-0.05% (calculated on raw material, enzyme activity 100,000 units).

Packaging, storage and shelf life

The product is packed in plastic drums, 25kg/drum for liquid form and 20kg/bag for solid form.

This product is a biological active substance, under high temperature, strong acid, strong alkali will cause enzyme inactivation. Therefore, during transportation and storage, the product should be protected from sunlight and moisture. The warehouse must be kept clean, cool and dry.

Evaluate LIPASE – ENZYME FOR PAPER INDUSTRY

There are no reviews yet.